In today's fast-paced digital printing industry, efficient and high-quality finishing is crucial for short-run jobs demanding quick turnaround times. Creasing, vital for preventing damage and ensuring a professional finish, is often a bottleneck. The Formax Atlas C100 and C200 auto-feed creasers offer a powerful solution, addressing the need for speed, accuracy, and durability in high-volume digital print finishing. These machines streamline the creasing process, significantly improving workflow and ultimately, the quality of the final product.This detailed review explores the features and capabilities of both the C100 and C200 models, highlighting their user-friendly interfaces, robust construction, and versatile functionalities. We'll delve into the ease of setup, the precision of the creasing mechanism, and the added benefit of integrated perforation capabilities. Discover how these auto-feed creasers can elevate your print finishing process, delivering consistent, professional results and maximizing your productivity.

Pros And Cons

- Accurate

- Powerful

- Durable

- Easy to use

- Larger sheet capacity (up to 19 inches wide)

- 7-inch color touchscreen for quick and easy setup and automatic adjustments

- Pre-programmed for six popular crease types in three different sizes

- Allows programming and saving of unlimited custom jobs

- Accurate

- Powerful

- Durable

- Easy to use

- 7-inch color touchscreen for quick and easy setup and automatic adjustments

- Pre-programmed for six popular crease types in three different sizes

- Allows programming and saving of unlimited custom jobs

Read more: Top 5 Paper Folding Machines for Perfect Newsletters

Precision Creasing for High-Volume Digital Finishing

In today's fast-paced print world, on-demand digital printing is the norm, particularly for short-run jobs needing quick turnaround times. To maintain professional quality, proper finishing is paramount. Creasing is essential for preventing cracking and tearing in folded pieces, ensuring a clean, high-quality final product.

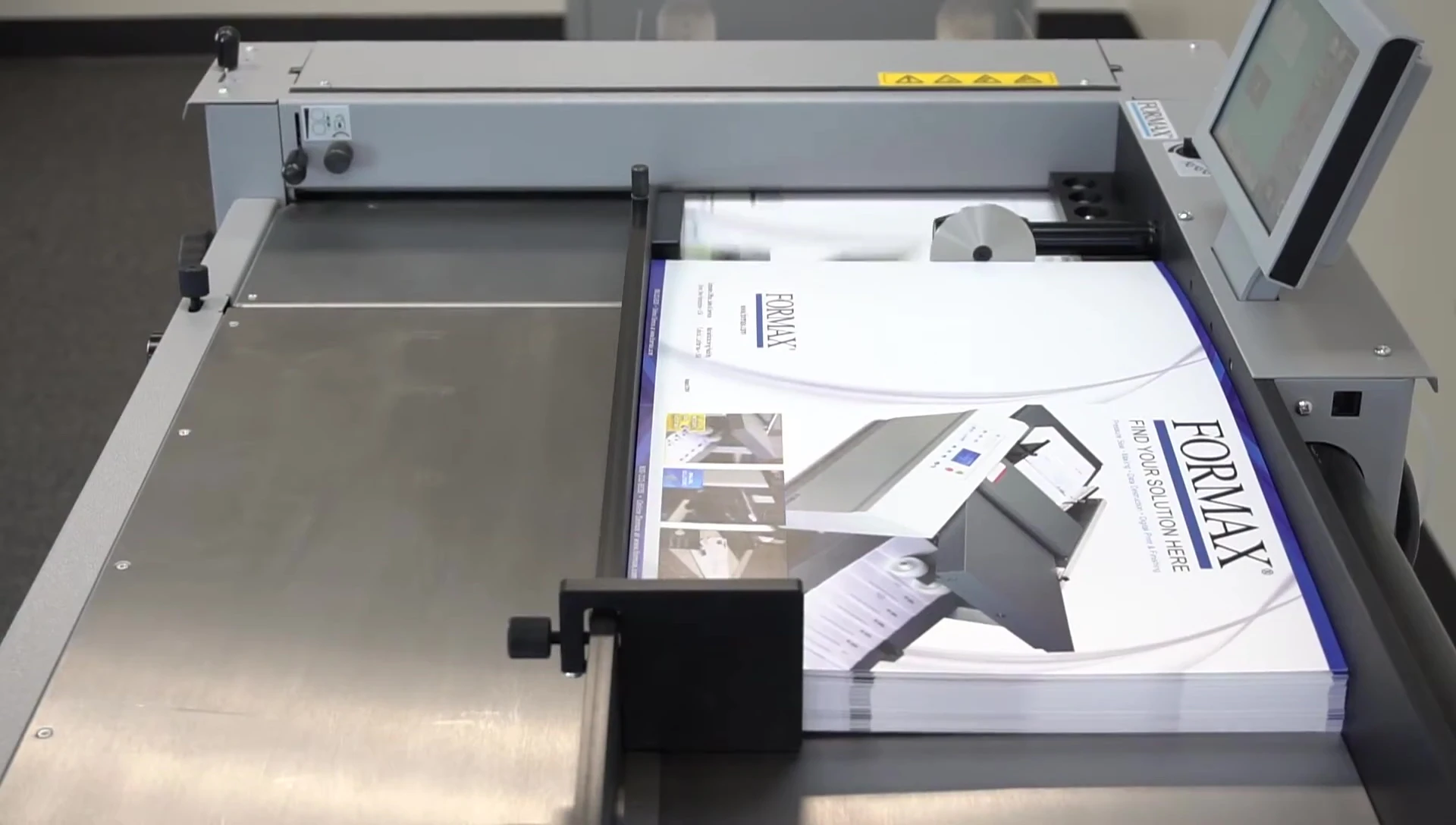

The Atlas C100 and C200 automatic feed creasers are designed to meet these high-volume demands, offering accuracy, power, and durability. They effortlessly handle the creasing needs of digital print finishing, resulting in a professional, high-quality look that leaves a lasting impression.

Powerful Air Suction Feed System and User-Friendly Interface

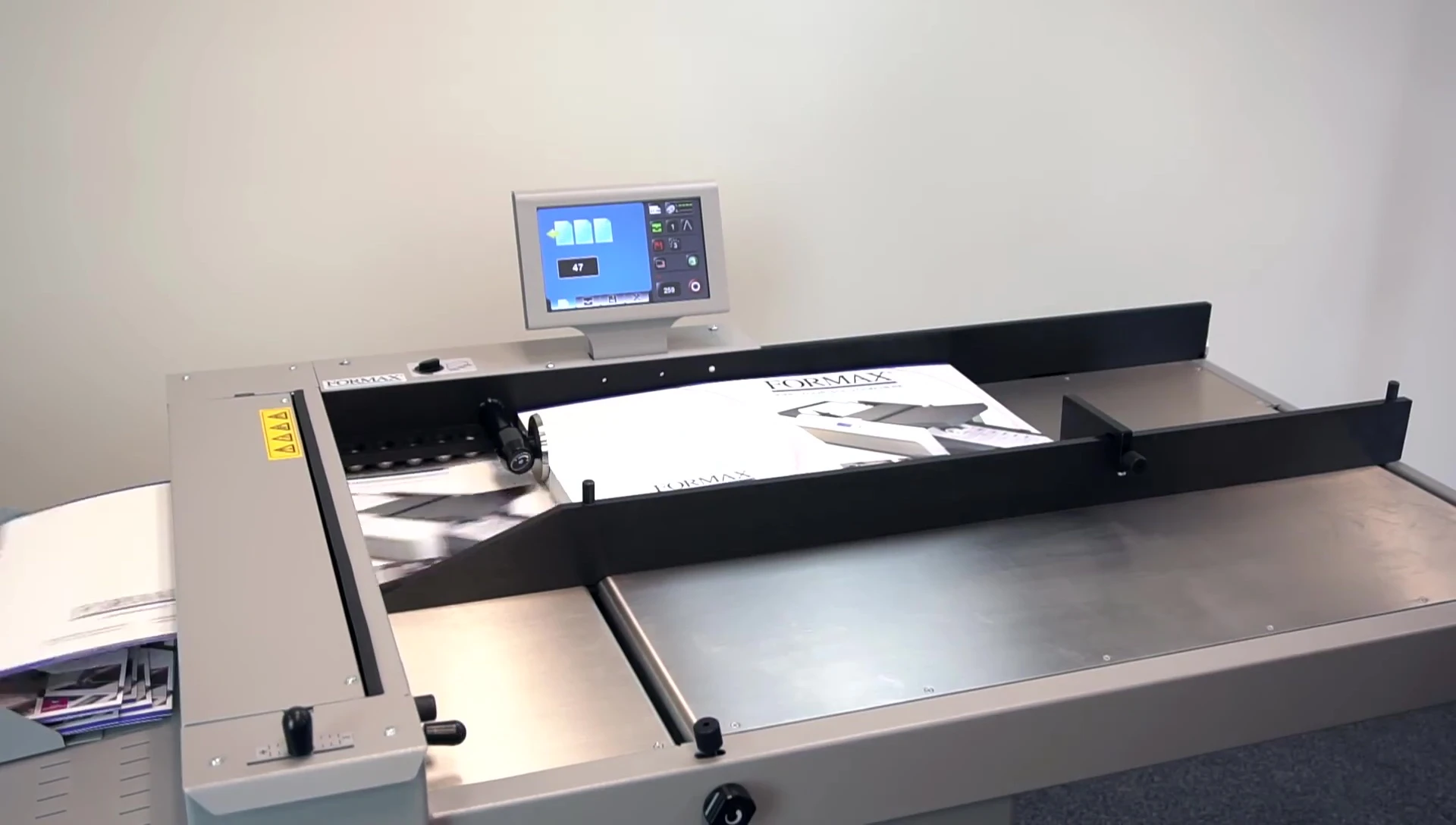

Both the C100 and C200 models boast a robust air suction feed table with an alignment deck. This ensures consistent and accurate feeding of paper weights up to 400 gsm. The 7-inch color touchscreen provides intuitive control, enabling quick and easy setup and automated adjustments, simplifying the entire process.

The user-friendly interface minimizes setup time and allows for easy adjustments based on paper type and job requirements. This streamlined approach enhances efficiency and reduces downtime, maximizing productivity in a busy printing environment.

Setup and Operation: A Step-by-Step Guide

Setting up the air feed table is straightforward, involving five simple steps: adjusting the infeed gap, setting the side guides, positioning the rear guide, adjusting side air volume, and regulating the suction. These steps ensure optimal paper handling and prevent jams.

The intuitive design guides users through each step, providing clear instructions. Detailed visuals and helpful prompts ensure even novice users can successfully set up and operate the creaser efficiently.

Creasing Configurations and Customization

The Atlas C100 and C200 come pre-programmed with six popular crease types in three different sizes, including a setting for perfect bound book covers. The ability to program and save an unlimited number of custom jobs offers unparalleled flexibility.

Users can tailor the creasing settings to specific project requirements, ensuring optimal results for various applications. This customization feature increases versatility and adapts to diverse printing needs.

Robust Design and Perforation Capabilities

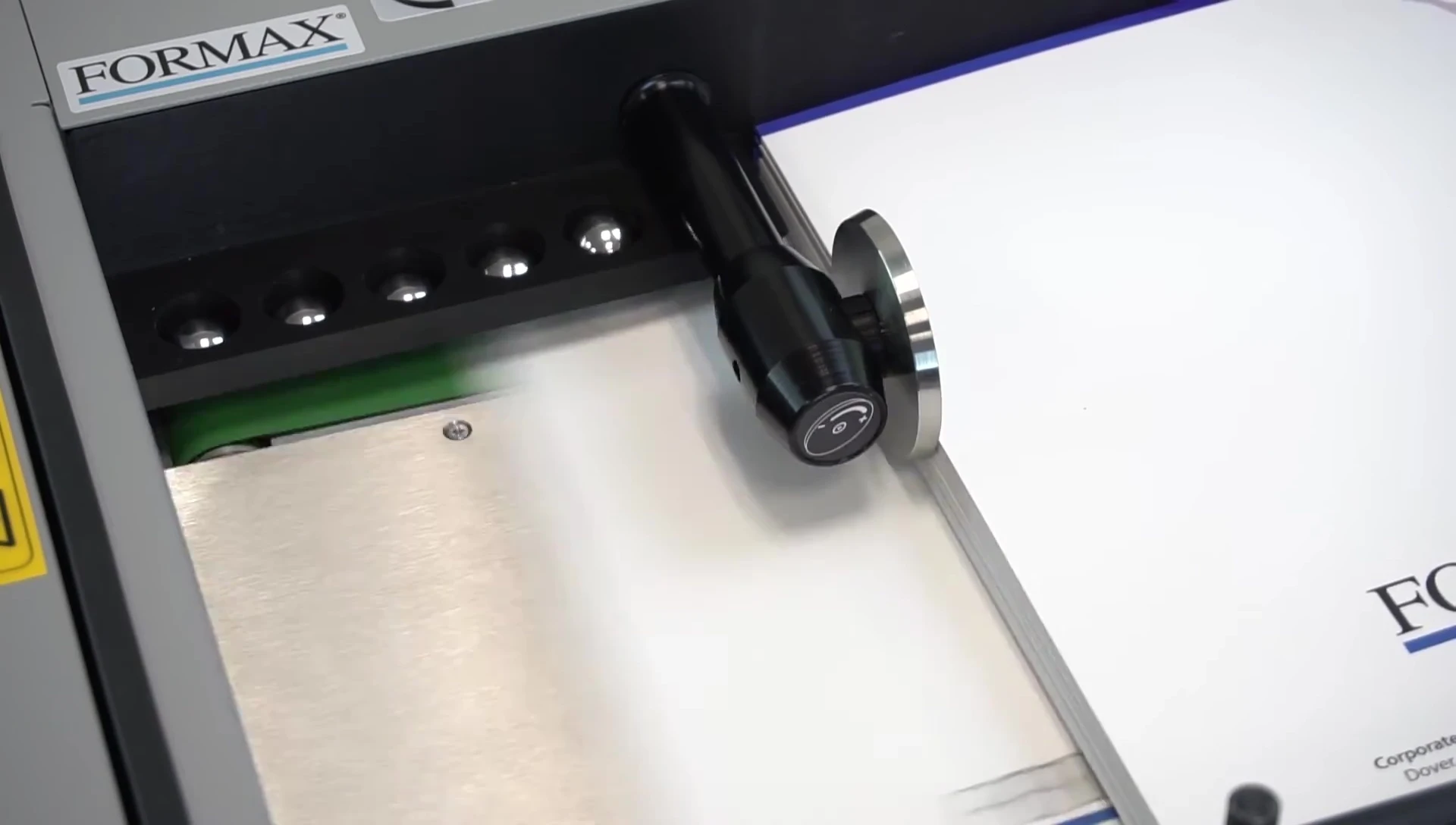

The creasers feature a heavy-duty creasing mechanism using a channel and anvil for precise crease creation. A perforator tool is included, easily attached to add perforations simultaneously with creasing.

The durable construction ensures long-term reliability, while the added perforation capability expands functionality, increasing efficiency and reducing the need for separate equipment.

Conclusion: Are the Atlas C100 and C200 Right for You?

The Formax Atlas C100 and C200 auto-feed creasers offer a compelling combination of ease of use, power, and accuracy. Their intuitive interface, robust design, and versatile features make them ideal for high-volume digital finishing.

The main difference lies in sheet capacity, with the C200 handling larger sheets (up to 19 inches wide). Whether you choose the C100 or C200 depends on your specific needs and budget. Both models represent a significant investment in improving print finishing workflow and quality.