This guide provides comprehensive instructions for setting up, troubleshooting, and maintaining the Martin Yale 1611 folding machine. From initial assembly and paper guide adjustment to resolving common issues like paper jams and skew problems, this resource covers all aspects of 1611 operation. Whether you're a first-time user or an experienced operator seeking maintenance tips, you'll find valuable information to optimize your folding process. We cover essential setup procedures, including installing the fold tables and exit tray, and adjusting the paper guides for accurate folding.The guide also details troubleshooting techniques for common problems such as paper jams and inaccurate folding. Learn how to adjust the retarder for optimal paper feeding, correct skew issues for straight folds, and perform regular cleaning and lubrication to maximize machine lifespan and efficiency. With clear, step-by-step instructions and helpful illustrations (where applicable), this guide empowers users to keep their Martin Yale 1611 running smoothly and reliably.

Pros And Cons

- Easily installed fold tables, tray extension, and exit tray with locating pins.

- Incorrect installation of the second fold table can prevent it from working.

- Paper jams may occur if the second fold table is not installed correctly.

- Overtightening the retarder can damage the feed wheel.

- If the retarder is too loose, multiple sheets can feed and jam the machine.

Read more: Top 5 Paper Folding Machines for Perfect Newsletters

Setting Up the Martin Yale 1611 Folding Machine

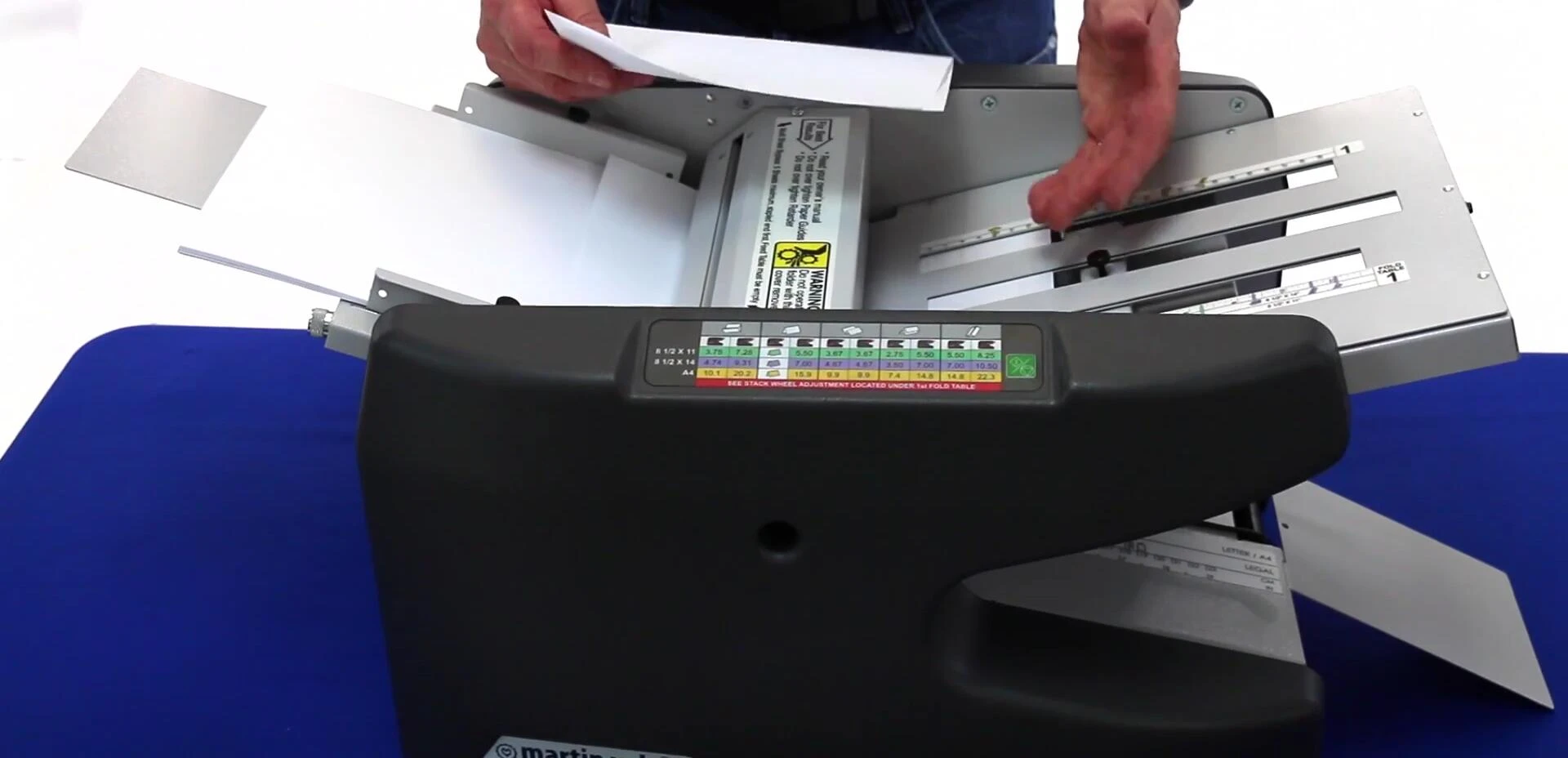

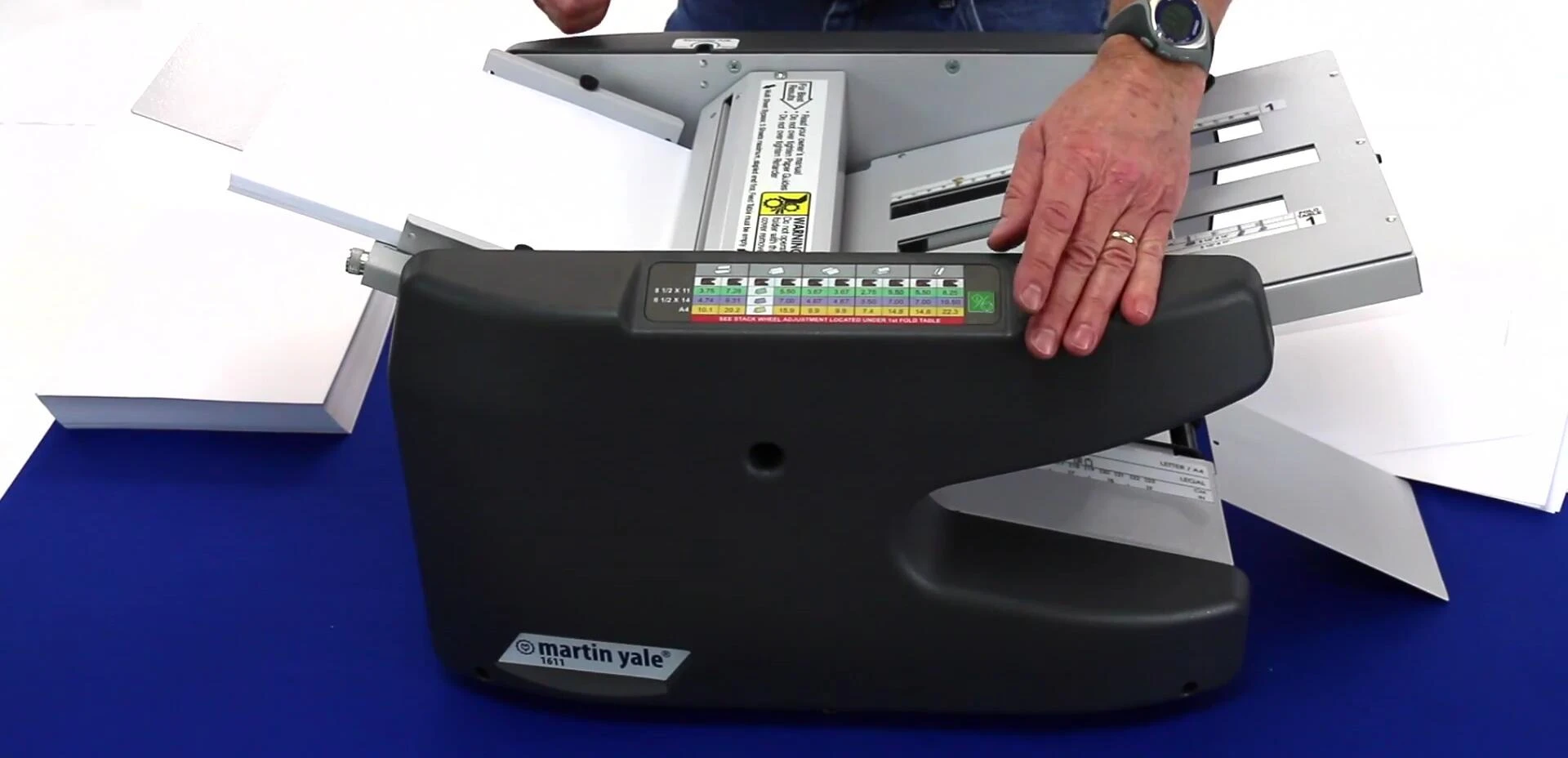

Before setting up the Martin Yale 1611 folding machine, ensure the paper guides are correctly adjusted to the paper width. Confirm the paper guides are snug against the paper. Set the first and second fold tables to your desired folding positions. Finally, use the chart on the exit tray to adjust the stacking wheels to the correct position for your chosen fold type. This ensures smooth and accurate folding.

The 1611 arrives unassembled; you will need to install the two fold tables, tray extension, and exit tray. These components have locating pins for easy installation. Simply slide them into the designated slots until they securely click into place. Remember to install the second fold table using the lowest pins to avoid interference with the paper feed pressure adjustment.

Troubleshooting Paper Jams

If a paper jam occurs, remove the two Phillips head screws on the top cover to access the inside of the machine. Remove the top cover and fold tables to clear the jam. If the paper is difficult to remove, insert a large flat-tip screwdriver into the side hole to gently dislodge it. Gently turn the rollers counterclockwise to help feed the jammed paper back out.

Retarder Adjustment (Sheet Separator)

To adjust the retarder (sheet separator), remove the top cover. Insert a single sheet into the feed tray and manually feed it using the blue feed wheel. There should be a slight resistance; the paper shouldn't slip out easily or tear. If the adjustment is needed, use the included Allen wrench (9/64 hex) to make small adjustments. Tightening too much can damage the feed wheel, while making it too loose causes multiple sheet feeds and jams.

Only make minor adjustments. Over-tightening the retarder will damage the feed wheel, and if it's too loose, it will feed multiple sheets at once, resulting in jams. Always test the adjustment before making further changes.

Skew Adjustment

To adjust skew, set the machine for a half-fold. If the paper is twisted or uneven, adjust the skew. You can make small adjustments to the skew control and then run a test fold or observe the paper while folding. If the paper puckers on one side, it indicates the paper is feeding sideways. Correct this by adjusting the skew until the paper feeds straight and folds cleanly.

You can adjust the skew while the machine is running by observing the paper. If the paper puckers on one side, it is a clear sign that the skew adjustment needs correcting. Continue making small adjustments until the paper feeds straight.

Cleaning and Maintenance

To clean the Martin Yale 1611, remove the top cover and fold tables. Remove any paper residue. Clean the rollers using the Martin Yale rubber roller cleaner (item 200) and a cotton cloth, or a solution of hot water and dish soap. For stubborn dirt, use a non-metallic Scotch-Brite pad. Clean the blue rubber rollers with alcohol. Finally, lubricate the machine with light machine oil, applying a drop where the shaft meets the bronze bushing on each roller.

Regular cleaning and lubrication are crucial for maintaining the performance and longevity of your folding machine. This procedure helps prevent jams and ensures smooth, efficient operation. Remember to follow the recommended cleaning products and methods for best results.

Conclusion

The Martin Yale 1611 folding machine, while requiring some initial setup and assembly, is a robust and reliable machine. Its straightforward design makes maintenance easy, and the troubleshooting guide covers common issues. Regularly cleaning and lubricating the machine ensures smooth operation and prevents issues. This detailed guide assists users in setting up, operating, and maintaining the 1611 effectively.