This comprehensive guide provides a step-by-step walkthrough for loading Brady bulk box labels into your Brady label printer. Whether you're a seasoned user or a first-timer, this guide will ensure a smooth and efficient loading process, minimizing downtime and maximizing productivity. We cover everything from selecting the correct box and verifying compatibility with your printer model (such as the m611, bmp61, or bmp71) to the precise placement of the label roll and the crucial role of the material ramp.Mastering the art of loading Brady bulk box labels unlocks the significant cost savings and time efficiency these labels offer. This guide clarifies the seemingly simple process, transforming potential frustration into a streamlined workflow. By following these clear instructions, you'll confidently load your labels, optimizing your printer's performance and reaping the benefits of high-volume, cost-effective label printing. Let's dive into the details and ensure your Brady printer is ready for peak performance.

Pros And Cons

- Save time and money

- Compatible with Brady's M611, BMP61, and BMP71 label printers

- Loading instructions on the box

- High output for a variety of applications

Read more: Top 10 Best Label Printers 2018: A Detailed Review

Choosing the Right Box for Your Brady Printer

Brady offers various bulk box labels compatible with their popular label printers. Selecting the correct box is crucial for seamless integration and efficient label printing. Ensure the box clearly indicates compatibility with your specific Brady printer model (like the m611, bmp61, or bmp71). This initial step eliminates potential compatibility issues.

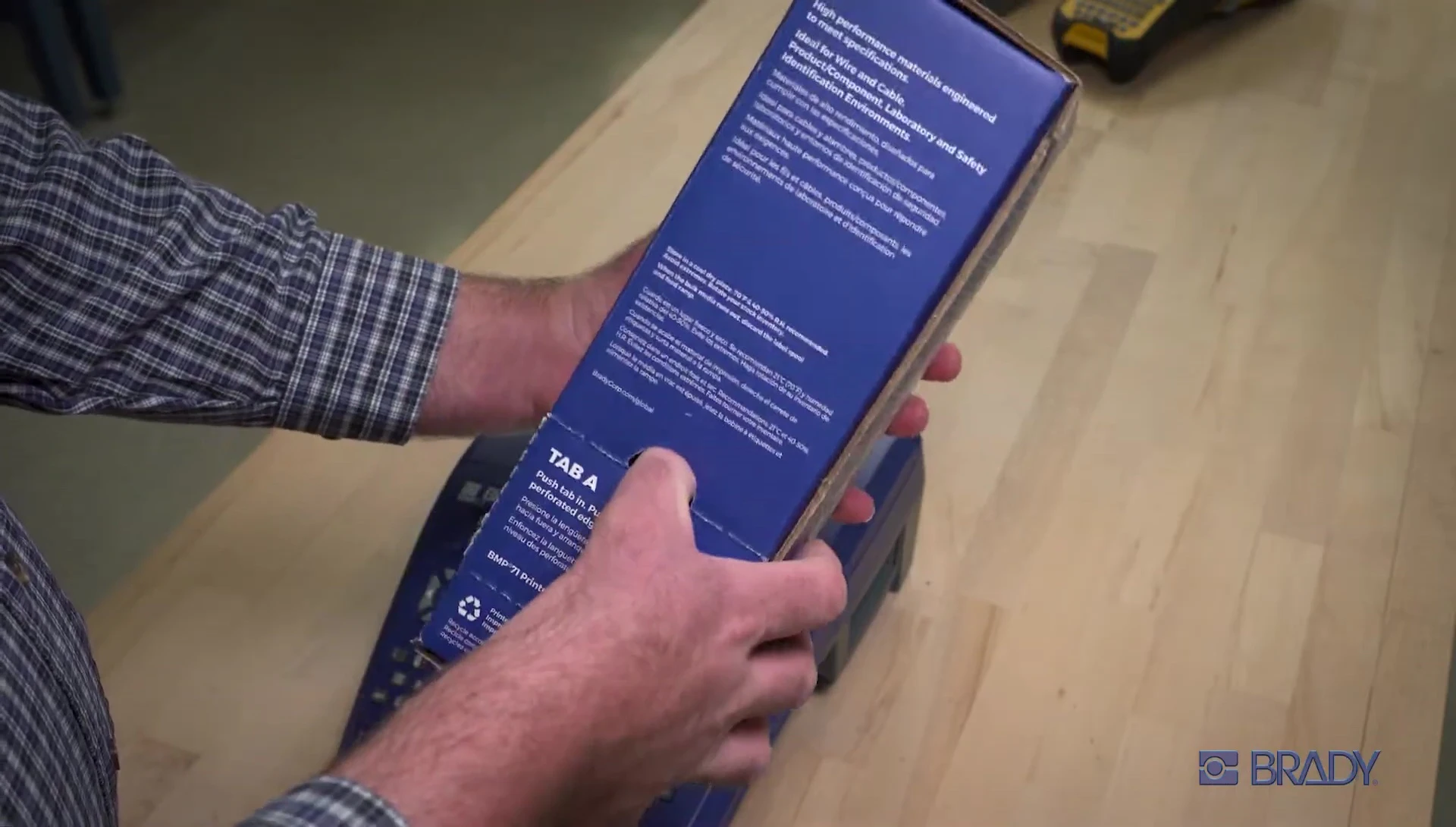

The packaging itself provides valuable information. Check the back of the box for clear loading instructions. This eliminates guesswork and ensures a smooth setup process for even first-time users. Take note of any special markings or features on the packaging.

Preparing the Label Box for Loading

Before loading the labels, you must prepare the box. Open the box and carefully remove the tab that matches your printer's specifications. Ensure the leading edge of the label roll is easily accessible for proper alignment within the printer mechanism. This is a critical step to avoid misalignments or jams.

Next, attach the material ramp. This ramp assists in aligning the label material with the printer rollers, ensuring smooth feeding. Proper placement of the ramp is essential to maintain print quality and avoid potential issues.

Loading the Labels into the Printer

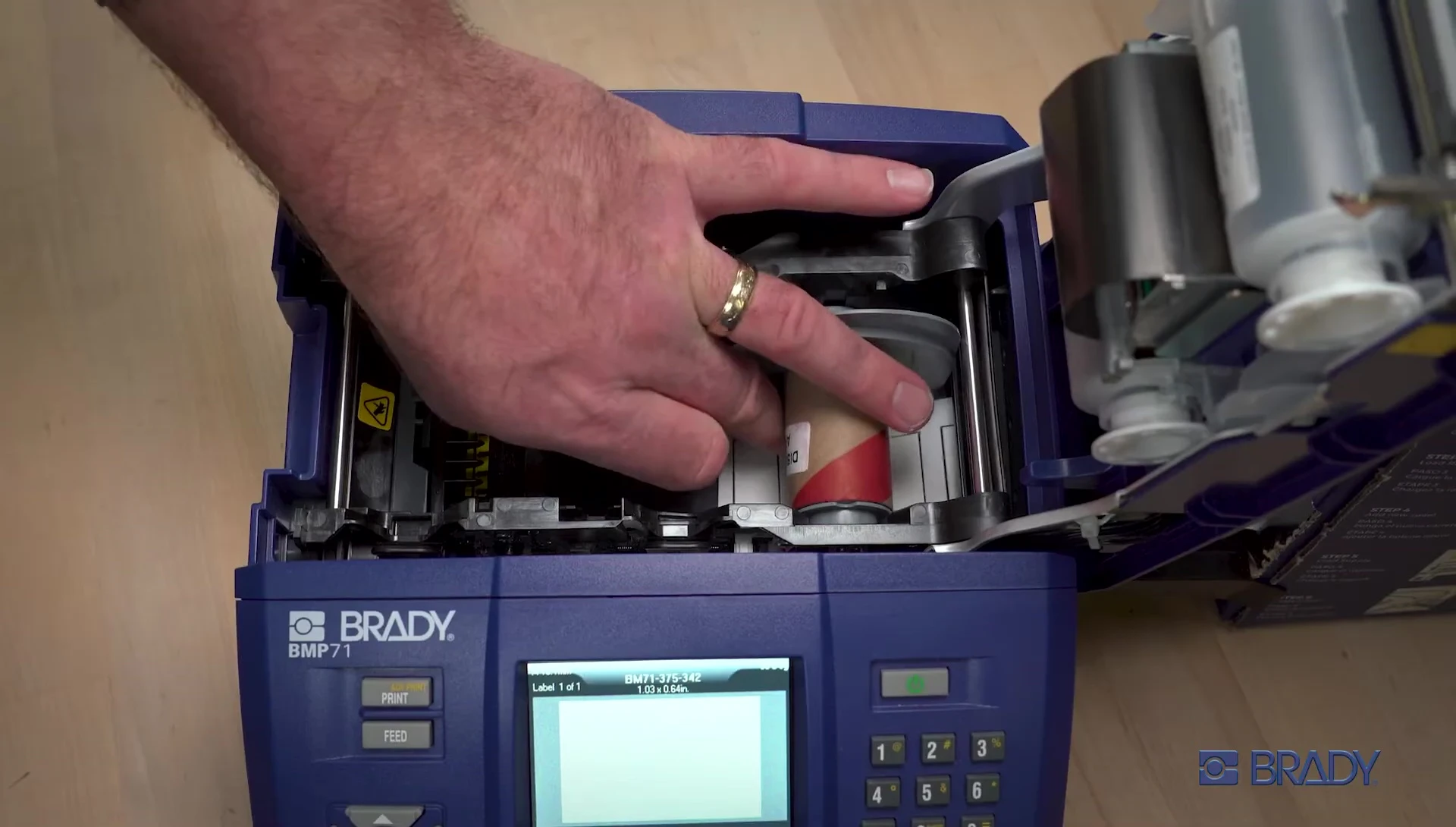

Open your Brady printer and insert the label spool. Pay close attention to aligning the print smart chip for optimal functionality. This step ensures the printer correctly identifies the label type and settings for accurate printing.

Begin feeding the labels through the material slot, guiding them carefully. Stop at the marked arrow inlet. This precise feeding process is crucial for a smooth printing operation. Close the printer door once the labels are correctly positioned.

Conclusion: Brady Bulk Labels – Are They Worth It?

Brady's bulk box labels offer a cost-effective and time-saving solution for high-volume label printing. The clear instructions and included ramp facilitate easy loading, minimizing downtime. The compatibility with various Brady printer models ensures broad applicability.

While the initial investment in bulk labels might be higher, the long-term savings in cost per label and increased efficiency make them a worthwhile choice for businesses with significant labeling needs. The focus on user-friendliness and efficient design makes these labels a smart purchase for most users.