Shipping costs are a significant factor for businesses and individuals alike, often impacting profit margins and overall budget. A seemingly small detail, choosing the right box size, can dramatically influence these costs, significantly reducing wasted space and unnecessary expenses associated with oversized packaging. Incorrectly sized boxes lead to higher shipping fees due to increased weight and volume charges, as well as increased risk of damage during transit from excessive movement within the package. Finding the perfect balance between adequate protection and efficient use of space is crucial for optimizing your shipping process.

This seemingly simple task, however, requires careful consideration of several factors. In this article, we will guide you through a step-by-step process to determine the ideal box size for your specific shipping needs, ensuring you save money and enhance the overall shipping experience. We'll explore measuring your items accurately, selecting appropriate packaging materials, and understanding the various carrier size and weight restrictions to achieve optimal efficiency.

Preparation and Safety Guidelines

- Measuring tape

- Packaging materials (tissue paper, bubble wrap, inserts)

- Custom printed boxes (optional)

- Avoid oversized boxes: Using boxes that are too large allows for excessive shifting during transit, increasing the risk of damage. Fill any extra space with sufficient packing material.

- Consider item fragility: Fragile items require more robust boxes and ample cushioning. Choose a box appropriate for the weight and fragility of your contents.

- Double-box valuable or easily damaged items: For high-value or delicate goods, using a double box system (placing the item in a smaller box within a larger one) provides an extra layer of protection.

Step-by-Step Instructions

Measure Product Dimensions

- Determine the length, width, and depth of your product. If shipping multiple items, measure them as they will be arranged in the box.

Measure Product Dimensions Assess Fragility and Void Fill Needs

- If your product is fragile, choose a box large enough for void fill (tissue paper, bubble wrap, inserts).

Assess Fragility and Void Fill Needs Select Appropriate Box Size

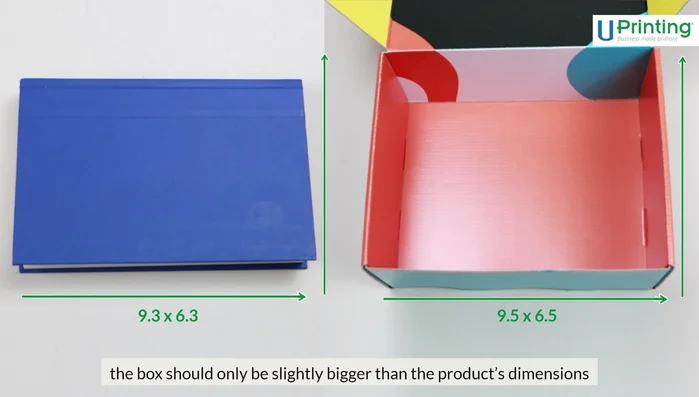

- For non-fragile items, select a box slightly larger than the product's dimensions for a snug fit. For fragile items, allow for ample void fill.

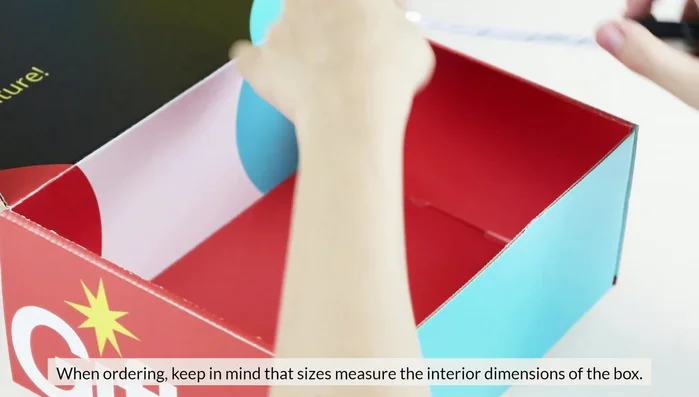

- Remember that box sizes typically refer to interior dimensions. Ensure everything fits snugly inside.

Select Appropriate Box Size Package and Secure Item

- Use adequate packaging materials (tissue paper, bubble wrap, etc.) to secure the item and prevent movement within the box. This also reinforces your brand.

Package and Secure Item Explore Custom Box Options

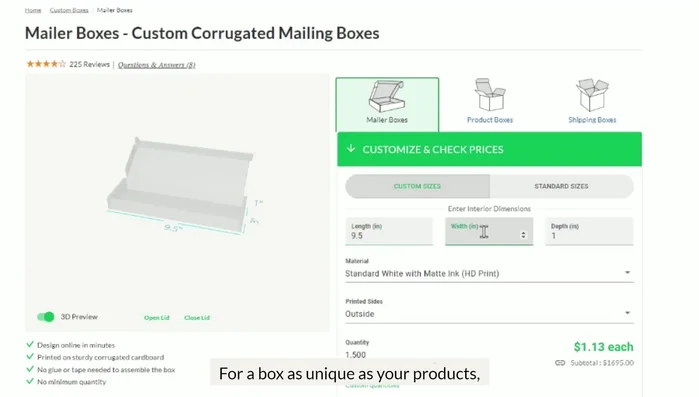

- For optimal efficiency and branding, explore custom-sized printed boxes to eliminate unnecessary space and void fill.

Explore Custom Box Options

Read more: Upcycling Padded Envelopes: A Trash-to-Treasure Craft Project

Tips

- Start by assessing the size and fragility of your item.

- A box that is just the right size reduces shipping costs and void fill.

- Proper packaging not only protects your product, but enhances your brand image.