Shipping countless packages? Tired of messy handwritten labels and the inevitable smudges and misreads? Investing in a thermal shipping label printer can revolutionize your shipping process, saving you time, money, and a considerable amount of frustration. From small businesses just starting out to large e-commerce operations, the right thermal printer can streamline your workflow and improve efficiency dramatically. Choosing the best one, however, can feel overwhelming with the sheer number of options available. Different features cater to varying needs and budgets, making the selection process crucial.

This buyer's guide will navigate you through the key factors to consider when choosing a thermal shipping label printer, helping you determine which features are essential for your specific requirements. We'll explore crucial aspects like print speed, label size compatibility, connectivity options, and overall reliability. Ready to find your perfect match? Let's dive into a step-by-step process to help you select the best thermal shipping label printer for your needs.

Preparation and Safety Guidelines

- Thermal Shipping Label Printer

- Always use thermal-resistant labels specifically designed for your printer model. Using incorrect labels can damage the printhead and void your warranty.

- Never touch the printhead directly. The thermal printhead is sensitive and can be easily damaged by oils from your skin.

- Ensure proper ventilation around the printer to prevent overheating, especially during high-volume printing. Overheating can shorten the lifespan of the printer and potentially cause a fire hazard.

Step-by-Step Instructions

Connectivity

- USB, Ethernet, Wi-Fi, and Bluetooth.

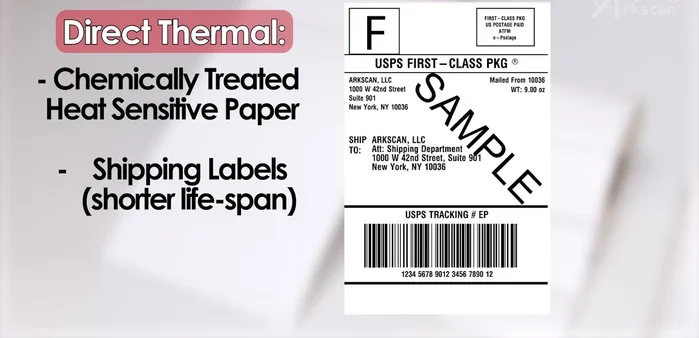

Connectivity Label Type

- Direct Thermal vs. Thermal Transfer. Direct thermal is suitable for shipping labels with shorter lifespans.

Label Type Label Compatibility

- Use Zebra or ArcScan compatible labels with a gap or black mark for optimal compatibility with ArcScan printers. Blank backside labels work best.

Label Compatibility Label Handling

- Check if the printer supports both fan-fold and rolled labels.

Label Handling Print Quality

- Use a DPI of 203 for shipping labels and 300 for product labels.

Print Quality Automation

- If needed, consider a printer with an auto peel function.

Automation

Read more: Quick Fix: Reset Your Label Printer for Disconnect Issues

Tips

- USB offers fastest printing speed but limits to one computer.

- Ethernet provides network sharing and higher security but requires direct network connection.

- Wi-Fi allows placement anywhere with Wi-Fi signal but has printing delays.

- Bluetooth is wireless but limited to one connection and doesn't support Mac/Linux.

- Check device and shipping platform compatibility.